-

11/5/17 - The build starts by ripping the wood into stringers, ribs, and the keelson.

-

11/6/17 - The shape of temporary forms are transferred from the plans to wood.

-

11/8/17 - A strongback is set up.

-

Two parts of the transom are created and fiberglassed.

-

Two parts of the transom are created and fiberglassed.

-

Temporary forms are set up.

-

11/11/17 - The keelson and 10 stringers are placed on the temporary frames.

-

11/13/17 - The first few ribs are steamed and epoxied in place.

-

11/14/17 - My setup for steaming the ribs.

-

All of the ribs have been steamed, bent, and pushed into place.

-

11/15/17 - The ribs are epoxied to the stringers in stages.

-

11/17/17 - The boat is removed from the temporary frames.

-

11/19/17 - The overhanging ribs are cut off and inwale spacer blocks are epoxied to the gunwale.

-

11/20/17 - The inwales are epoxied in place.

-

11/21/17 - The meranti breasthook is installed.

-

The meranti transom knees are installed.

-

The middle seat cross pieces are installed.

-

11/22/17 - Seat support pieces are test fit.

-

Support pieces are reinforced with pieces of marine plywood.

-

11/28/17 - The modified aft seating area is created out of paulownia and cedar strips.

-

The forward seat is made from cedar strips.

-

11/29/17 - The inside of the daggerboard trunk pieces is fiberglassed.

-

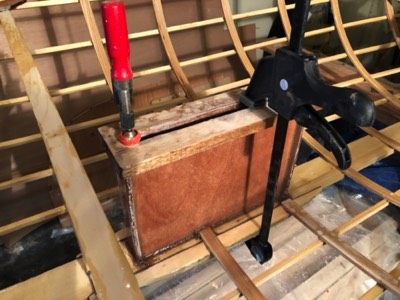

11/30/17 - The daggerboard trunk is epoxied together.

-

12/1/17 - The seats are sanded and prepped for fiberglassing.

-

Forward seat is ready to be fiberglassed.

-

The aft seating is fiberglassed.

-

Forward seat.

-

12/8/17 - The underside of the wood frame is sealed with epoxy and the keelson is fiberglassed.

-

12/12/17 - The daggerboard trunk is epoxied in place.

-

Overall shot of the boat to this point.

-

1/2/18 - The top piece of the daggerboard trunk is epoxied in place.

-

The forward seat is epoxied in place.

-

1/3/18 - The underside of the aft seat is ready for fiberglassing.

-

The fiberglass is saturated with epoxy.

-

1/4/18 - The aft seat is epoxied in place.

-

1/8/18 - The floorboards are cut and fitted.

-

The daggerboard is laminated from several strips of walnut and mahogany.

-

1/9/18 - The mast partner is laminated from several pieces of hardwood.

-

1/10/18 - The daggerboard is sanded and the handle shape is cut out.

-

1/11/18 - The skeg is laminted from two pieces of marine plywood.

-

1/12/18 - Oarlock brackets are shaped from pieces of walnut.

-

Mast step is shaped from a piece of walnut.

-

Mast step and oarlock brackets sealed are sealed with epoxy.

-

The floorboards are fiberglassed on one side.

-

The edge of the daggerboard is coated with a layer of thickened epoxy.

-

Mast partner is fiberglassed.

-

1/14/18 - The undersides of the floorboards and mast partner are sealed with epoxy.

-

The daggerboard is fiberglassed on one side.

-

1/16/18 - The aft floorboards are epoxied in place.

-

The forward floorboards are epoxied in place.

-

The flipside of the daggerboard is fiberglassed.

-

Oarlocks are epoxed in place.

-

1/17/18 - The mast is test fit.

-

The mast step place is determined.

-

Daggerboard trunk supports are epoxied in place.

-

Mast step is epoxied in place.

-

1/19/18 - The boat is almost finished!

-

2/16/18 - Pieces of spruce are scarfed together to form oar blanks.

-

2/24/18 - pieces of spruce are epoxied to either side of the shaped oar shaft.

-

Angles are cut in the blades.

-

One of the oars is shaped.

-

2/25/18 - A good before and after of the oars.

-

Thickened epoxy is applied around the tips of the oars to increase durability.

-

3/4/18 - The sail starts off as a stack of dacron.

-

The reef patches are taped to a panel.

-

The reef patches are sewed to two panels.

-

3/5/18 - All the panels are sewn together.

-

3/13/18 - pieces of ironwood are epoxied to the bottom of the daggerboard.

-

The ironwood is sanded smooth to match.

-

The first two kevlar fibers are strung and tightened on the hull.

-

3/16/18 - The entire hull is laced with kevlar strands.

-

The skeg is test fit.

-

3/18/18 - The ironwood pieces of the daggerboard are reinforced with fiberglass.

-

A gudgen spacer block is epoxied to the transom.

-

3/19/18 - The rudder is test fit upside down!

-

An adjustable rowing footbrace is rough cut.

-

The first side of the rudder is fiberglassed.

-

The first sides of the oar blades are ready for epoxy.

-

The rudder is saturated with epoxy.

-

The oar blades are saturated with epoxy.

-

3/20/18 - Holes for the footbrace are drilled.

-

Two sets are drilled so they also act as a hiking brace when sailing.

-

3/21/18 - The flipsides of the oars are fiberglassed.

-

A fill coat of epoxy is added.

-

3/22/18 - A layer of thickened epoxy is added around the edge of the rudder.

-

3/23/18 - Construction is complete! The boat will get the dacron skin next.

-

Classic 14

-

Classic 14

-

Classic 14

-

Classic 14

-

The sailing rig is test fit.

-

3/26/18 - A new mast is scarfed together from two pieces of Douglas Fir.

-

The Ceconite dacron is draped over the hull.

-

3/27/18 - The mast is fiberglassed on three sides.

-

The Ceconite has been heat shrunk and secured to the gunwales.

-

The skeg is screwed into place and glued with 5200.

-

3/28/18 - View from the bow.

-

The first coat of paint is applied to the dacron to waterproof it.

-

3/29/18 - The second coat of paint is applied.

-

A rubstrip is laminated from several pieces of walnut.

-

3/30/18 - The rubstrips are saturated with epoxy.

-

The rubrails are test fit.

-

3/31/18 - The mast partner and tiller are varnished.

-

The rudder is varnished.

-

The daggerboard is varnished.

-

The oars, spars, and rubrails are varnished.

-

4/1/18 - The boat is ready for varnish.

-

First coat of varnish is applied.

-

The opposite sides of the oars and spars are varnished.

-

4/3/18 - An eyesplice is tied at the head of the sail.

-

4/4/18 - The daggerboard is test fit.

-

4/8/8 - She fits on the new trailer nicely!

-

Another trailer view.

-

5/25/18 - New sail track is tested out.

-

Sail track eliminates the problem of the sail ties interfering with the snotter.

-

I came up with a system for getting the boom out of the way for rowing.

-

5/27/18 - Pieces of the new kick-up rudder are fiberglassed.

-

5/28/18 - The kick up rudder is test-assembled.

-

More parts are fiberglassed.

-

7/1/18 - The parts of the kick up rudder trunk are epoxied together.

-

7/2/18 - The kick up rudder is assembled for the first time.

-

7/18/18 - The rudder is varnished.

-

The rudder is mounted on the boat for the first time.

-

The kick up feature works great.

-

7/19/8 - The old fabric covering is stripped off.

-

Bare bones again.

-

8/3/18 - The side seats have been cut out.

-

8/6/18 - Extra floor boards are fiberglassed.

-

8/7/18 - Extra floor boards are installed.

-

8/8/18 - One more set of floorboards.

-

8/13/18 - New Ceconite Dacron is laid on the hull.

-

The fabric is heat shrunk onto the hull.

-

6oz fiberglass cloth is laid on top of the Ceconite

-

The fiberglass is saturated with epoxy.

-

View of the bow.

-

8/15/18 - The skeg is epoxied in place.

-

8/16/18 - The first coat of primer is applied.

-

8/28/18 - A piece of Ceconite is used to cover floatation foam mounted under the stern seat.