-

1/25/21 - The kit is unpacked.

-

The #panels are epoxied to full length.

-

1/28/21 - Hull panels #2 and #3 are epoxied to full length.

-

2/1/21 - Hull panels 1 and 2 are wired in place with the temporary frames.

-

2/3/21 - # 3 Hull Panels are wired in place.

-

#4 panels are wired in place.

-

2/4/21 - The hull is flipped and all wires tightened.

-

2/5/21 - The seams are filled with epoxy.

-

2/10/21 - Fiberglass cloth is laid on the interior of the hull.

-

The cloth is saturated with epoxy.

-

2/11/21 - The fiberglass is trimmed and two layers of cloth are laid in the middle section of the boat.

-

The two layers of cloth are saturated with epoxy.

-

2/15/21 - The deck panels are epoxied to full length.

-

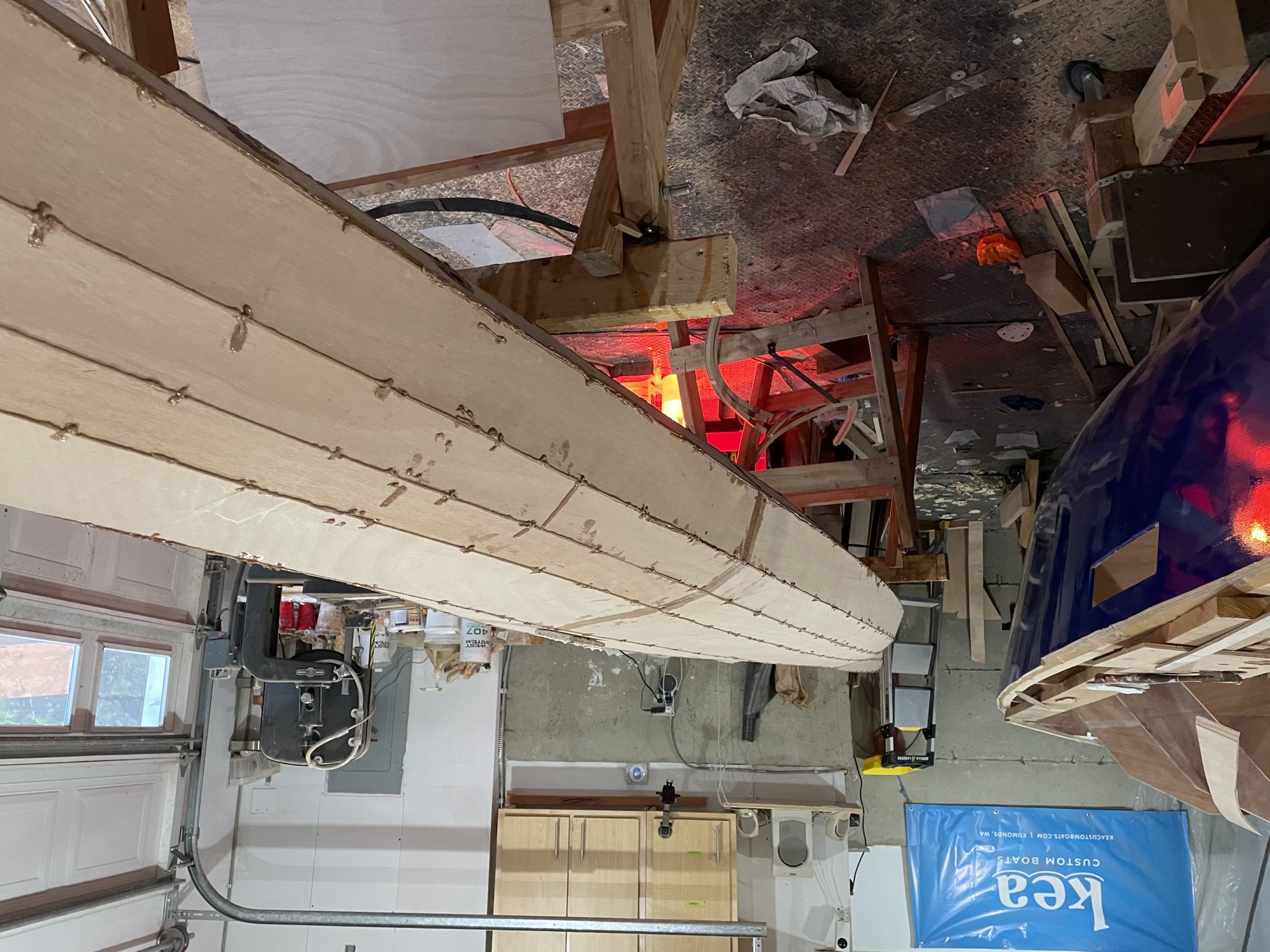

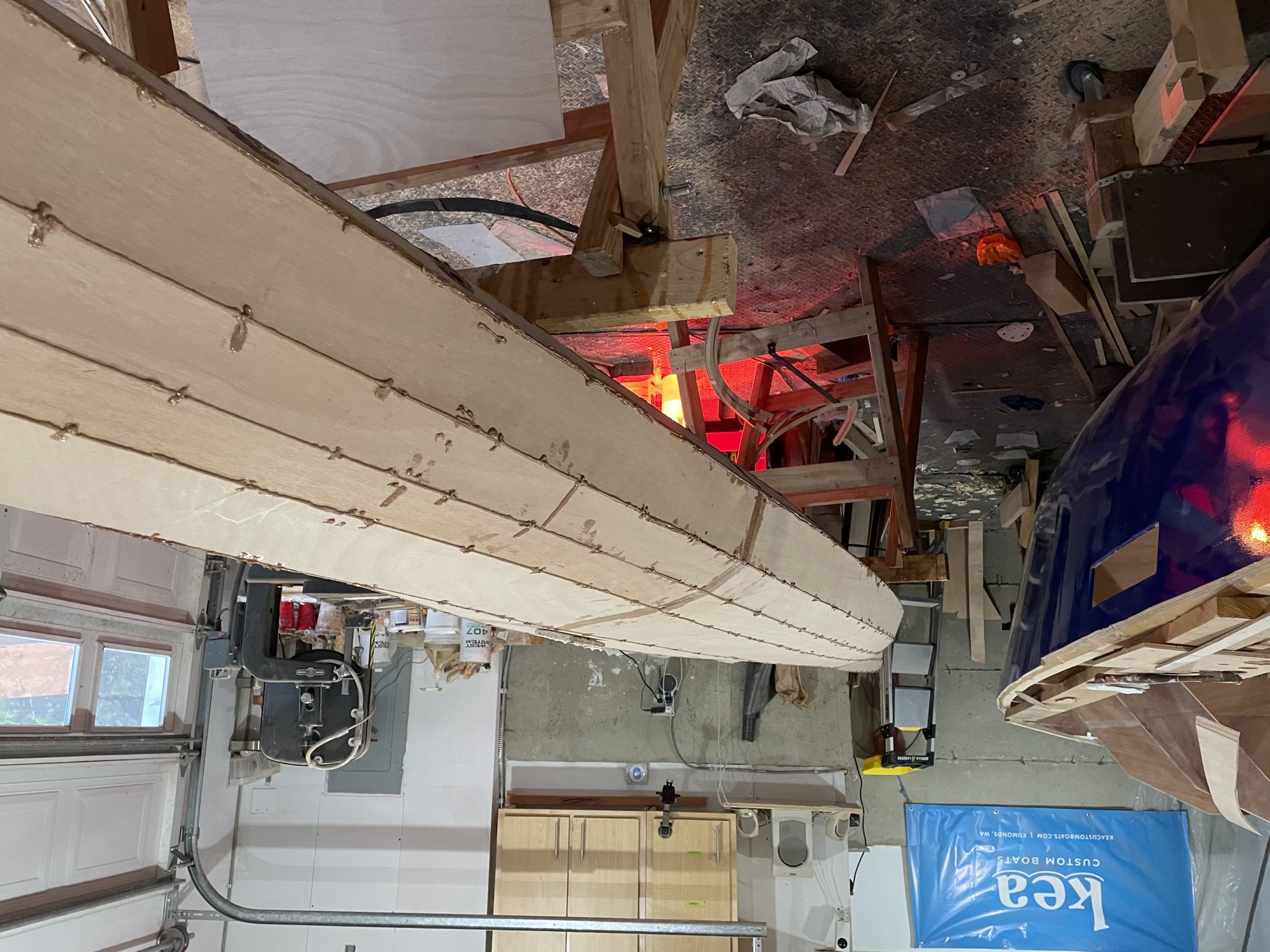

2/18/21 - The deck is wired up.

-

2/19/21 - The deck seams are filled with epoxy.

-

2/22/21 - The underside of the deck is epoxied.

-

2/25/21 - Recessed deck fittings are cut, shaped, and sealed with epoxy.

-

2/26/21 - The forward footbrace studs are epoxied in place.

-

Recessed deck fittings are filleted.

-

3/1/21 - The deck is epoxied to the hull.

-

3/3/21 - The inner port side hull/deck joint is epoxied.

-

3/421 - The inner starboard side hull/deck joint is epoxied.

-

3/7/21 - Remaining gaps are filled with epoxy.

-

3/8/21 - The hull is partially sanded.

-

3/10/21 - Sanding is finished.

-

3/11/21 - Fiberglass cloth is laid on the hull.

-

The cloth is saturated with epoxy.

-

3/12/21 - A fill coat of epoxy is added.

-

3/15/21 - The deck is partially sanded.

-

The deck is fully sanded.

-

3/16/21 - Fiberglass is laid on the deck.

-

The fiberglass is saturated with epoxy.

-

The overhanging fiberglass is cut off along the tape.

-

3/17/21 - The deck is given a fill coat of epoxy.

-

3/18/21 - The rudder mount is test fit.

-

The front hatch is traced on the deck.

-

The bulkheads are fiberglassed.

-

3/19/21 - The footbrace studs for the aft seat are epoxied in place.

-

Hatch lips are fiberglassed.

-

3/21/21 - The forward coaming riser is epoxied in place.

-

3/22/21 - The aft coaming riser is epoxied in place.

-

3/23/21 - The coaming lips are epoxied in place.

-

3/24/21 - The forward coaming is half sanded.

-

The coamings are fiberglassed.

-

3/27/21 - End pours of epoxy are perfomed.

-

3/28/21 - The aft bulkhead is installed.

-

Forward bulkhead is installed.

-

The aft hatch lip is epoxied in place.

-

3/29/21 - The deck is partially sanded.

-

4/7/21 - The rudder system is set up. The last step before varnish.

-

4/8/21 - The hull is washed down.

-

First coat of varnish is applied.

-

4/10/21 - Several coats of varnish later.

-

4/11/21 - Deck is ready for varnish.

-

First coat of varnish is applied.

-

4/14/21 - Second coat of varnish is applied.

-

4/16/21 - The rudder is installed.

-

4/17/21 - The deck rigging and seats are installed.