-

3/9/22 - The boat as I got it.

-

The forward hatch well is stitched together.

-

3/11/22 - The hull is sanded.

-

The hull is fiberglassed.

-

3/14/22 - Fill coat of epoxy and an extra fiberglass rub strip is applied.

-

Fiberglass tube is installed as a place to attach a carrying handle.

-

3/17/22 - Holes and any gaps in the deck are filled with epoxy.

-

3/18/22 - The deck is sanded.

-

4 oz fiberglass cloth is laid on the deck.

-

The cloth is saturated with epoxy.

-

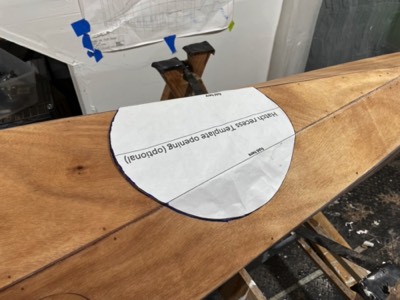

3/21/22 - Forward hatch opening is traced on the deck.

-

Hatch is cut out.

-

3/23/22 - The forward hatch recess is epoxied in place.

-

Coaming risers are epoxied in place.

-

3/24/22 - The forward hatch recess is sanded.

-

Coaming riser and aft hatch are sanded.

-

Forward hatch is fiberglassed.

-

Aft hatch is fiberglassed.

-

3/28/22 - Half of the hull is sanded.

-

3/30/22 - The coaming lip is epoxied in place.

-

3/31/22 - The coaming lip is fiberglassed.

-

4/1/22 - Exits for rudder cables are epoxied in place.

-

4/4/22 - The coaming is given a fill coat of epoxy.

-

4/11/22 - A coat of primer is applied.

-

3/12/22 - The primer is sanded.

-

First coat of paint.

-

4/16/22 - Red accent paint is applied.

-

4/21/22 - The backrest is installed.

-

4/27/22 - The rudder system is installed.

-

Hatch rims are epoxied in place.

-

4/28/22 - The hatch covers are put on and the boat is finished!