-

Ready for phase 2.

-

11/1/21 - The flip open sliding companionway hatch is done.

-

Overall shot with hatch in place.

-

12/21/21 - Painting of the interior is almost done.

-

12/26/21 - The Koru sees its first snow.

-

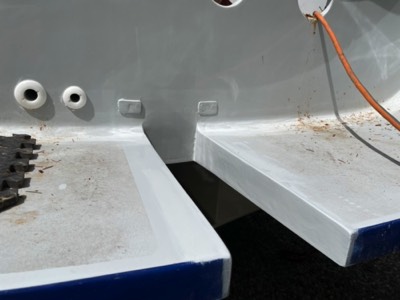

1/1/22 - Getting ready for the custom trailer bunks.

-

1/3/22 - The boat is lifted to make room for bunks.

-

And everything fits! The boat rides higher to create clearance for the lifting keel bulb and the electric pod drive.

-

Back in the parking spot.

-

1/5/22 - The interior has been painted with many coats of paint.

-

Galley area.

-

2/14/22 - The ePropulsion Pod dreive is mounted.

-

2/21/22 - Fans are mounted in the forward cabin.

-

Fans are mounted in the quarter berths.

-

2/24/22 - An important piece of equipment is installed.

-

2/25/22 - The forward area of the interior is complete, except for cushions.

-

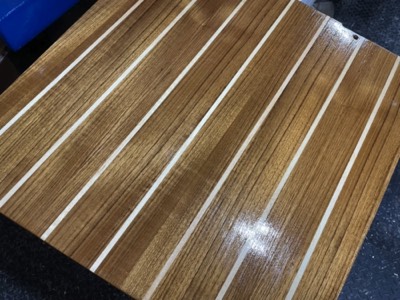

Sections of cabin sole are varnished.

-

3/6/22 - The forward berth area is complete.

-

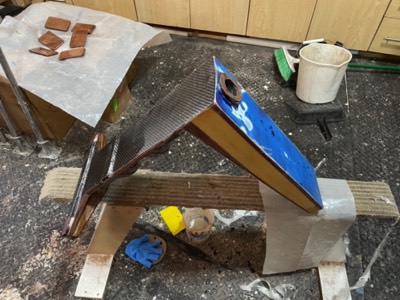

3/7/22 - Layup for a carbon fiber tube.

-

3/8/22 - Trimmed and ready for the next step.

-

The ladder is painted and varnished.

-

The head compartment is done.

-

3/9/22 - Phase 1 of the interior construction is done.

-

Looking into the quarter berths.

-

From the head into the galley.

-

Galley

-

With sink cutting board removed.

-

Electronics and chart table.

-

Looking toward the bow.

-

View from quarter berth.

-

View from forward cabin.

-

Galley from the companionway.

-

3/10/22 - Rudder from a J24 is cut to accept bronze rudder post.

-

3/12/22 - Cutout is partially filled with epoxy.

-

3/17/22 - Rudder is fiberglassed.

-

3/21/22 - Rudder support bracket is taking shape.

-

4/4/22 - Strips of sapele are ripped for the keel foil.

-

Half of the keel is laminated.

-

4/5/22 - Slot for the tilt up rudder is cut.

-

The rest of the keel foil is laminated.

-

4/9/22 - The pulpit and stanchions are test fit.

-

Deck level view.

-

Now it just needs pushpits.

-

4/12/22 - Pieces of wood are laminated on the upper part of the keel.

-

The chartplotter is mounted on the swing arm.

-

4/11/22 - The rudder bracket is laminated with carbon fiber.

-

4/13/22 - The rudder bracket is primed.

-

Rudder is primed.

-

4/14/22 - Rudder bracket hold down pins are test fit.

-

Tip of the rudder is painted red since it will be projecting behind the boat while on the trailer.

-

Access hatch is installed in deck.

-

4/16/22 - The rudder cutout is primed.

-

4/17/22 - The keel foil is sanded and filled.

-

4/20/22 - Opposite side of the keel foil is faired with epoxy.

-

4/21/22 - The keel is sanded and the styrofoam lead bulb mold is test fit.

-

The keel foil is fiberglassed on one side.

-

4/22/22 - The other side of the keel is fiberglassed.

-

4/23/22 - A layer of 12 oz carbon fiber is added.

-

4/28/22 - Starboard side of the keel foil is covered with carbon fiber.

-

Tiller is laminated from sapele and Alaskan yellow cedar.

-

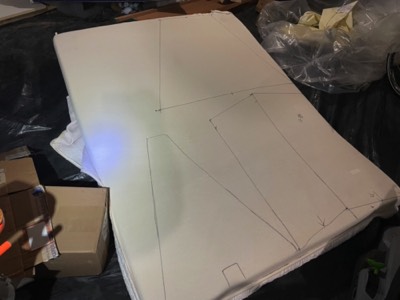

Lines are taken for the forward berth table/berth support.

-

Epoxy with graphite powder is applied.

-

A nice NACA foil shape.

-

4/29/22 - The tiller is sanded and rounded.

-

Rudder cutout is painted.

-

5/3/22 - Tiller is epoxy sealed.

-

5/12/22 - Lifeline stanchions are temporarily installed.

-

Painting of the rudder is complete. The tip is red because it will be sticking out beyond the stern when tilted up.

-

5/12/22 - Tilting rudder mount is installed.

-

5/23/22 - Table/berth support is cut out and test fit.

-

Support pieces for table are cut out.

-

5/24/22 - Port side of the keel foil is primered.

-

5/25/22 - The table/berth support is mounted on the mast support.

-

Mounted in the berth position.

-

Rudder is test fit in the tilted position for launch and recovery.

-

5/26/22 - Keel foil is painted with hard bottom paint.

-

5/27/22 - New retractable trailer straps are installed.

-

5/30/22 - The keel lifting footblock is temporarily mounted.

-

Winches are temporarily mounted.

-

Table/berth support is painted.

-

Cushion patterns for forward berth are traced out on a mattress.

-

6/4/22 - VHF/AIS system is installed.

-

6/5/22 - Starboard winch, clutch, and footblcok for keel lifiting are installed.

-

Stanchions and pulpit are installed.

-

6/8/22 - Mast crutch is tested using temporary mast.

-

6/9/22 - Navigation lights on pulpit are wired and tested.

-

6/11/22 - She's coming along!

-

Mast crutch system testing.

-

Custom pushpits are mounted.

-

Railing system is complete. Just add lifelines.

-

6/12/22 - The names are added!

-

View from above of names.

-

6/21/22 - Eye splice is created in keel lifting line.

-

The keel lifting system and keel foil are installed.

-

Keel in partially lowered position.

-

6/23/22 - Forward cabin table/berth is installed.

-

Table in lowered postion.

-

6/23/22 - The boat is at the riggers for mast and standing rigging.

-

7/18/22 - Beginning the process of getting the keel bulb out of the form.

-

Almost out.

-

Half of the keel bulb is out.

-

7/29/22 - Trying my hand at sewing cushion covers.

-

7/30/22 - Two more cushions.

-

8/8/22 - She's home from the riggers.

-

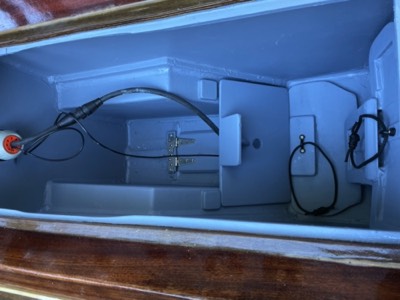

8/9/22 - The 5:1 internal outhaul system is installed in the boom.

-

8/11/22 - Mid mast support is made.

-

8/15/22 - Right side of the keel bulb is in place.

-

8/16/22 - Left side of the keel bulb is in place.

-

8/17/22 - Wires for antenna and masthead light are run through the mast.

-

Main sheet block is spliced onto the mainsheet.

-

8/29/22 - The bulb is bolted to the keel foil and then gaps are filled with epoxy.

-

8/30/22 - Blackout shade is installed on hatch.

-

Also serves as a fly screen.

-

Bulb is covered with epoxy and fairing additive.

-

9/1/22 - Mast raising system is tested out.

-

9/2/22 - The mast is up.

-

Bulb is given a coat of primer.

-

9/3/22 - First coat of antifoul paint on the bulb.

-

9/4/22 - Boom vang is installed.

-

9/4/22 - Just need some sails!

-

9/2/22 - The quarter berth is done.

-

Boom kicker is installed.

-

9/6/22 - The forward berth cushions are done.

-

She's ready for the Wooden Boat Festival!

-

New double slider hatch is installed.

-

Closed hatch.

-

9/16/22 - Toe rails are laminated from sapele.

-

Toe rails are epoxy sealed.

-

9/16/22 - The toe rails are test fit on the boat.

-

The sails have arrived!

-

9/18/22 - Improved mast crutch is ready.

-

9/19/22 - Jib is installed on the roller.

-

Jib is unfurled.

-

View of jib furled.

-

Main is raised for the first time. No battens were installed for this.

-

Cunningham is installed.

-

Both sails are up.

-

9/20/22 - Improved mast raising and lowering system works great.

-

9/30/22 - Hole is cut for retractable motor.

-

10/1/22 - Hole is cut in cockpit sole for access to motor.

-

10/2/22 - Motor door is test fit.

-

A little adjustment needs to be done.

-

Plug for sailing is test fit.

-

10/4/22 - lip to support access hatch is epoxied in place.

-

10/5/22 - Motor well walls are test fit.

-

Wall parts are fiberglassed.

-

10/6/22 - Motor well walls are test fit again.

-

10/9/22 - The forward wall of the motor well is mocked up.

-

All the joints in the motor well are filletted.

-

10/10/22 - View of pod drive temporarily mounted.

-

The motor well is primed with a barrier coat primer.

-

10/11/22 - The motor is mounted and in the retracted position.

-

The motor is locked in the down position.

-

The motor seen from below.

-

Cockpit sole hatch is in place.

-

10/23/22 - The final step of construction. Holes for the keel safety pins were drilled when the boat was launched. Now filled with carbon tubes which will be cut off.