-

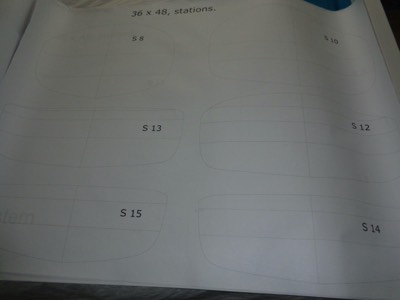

2/10/16 - The forms start as a print off on a large piece of paper.

-

2/12/16 - The form shapes are glued to particle board and are then cut out.

-

2/14/16 - The strongback is ready.

-

2/18/16 - The form risers are in place.

-

2/18/16 - The form risers are in place.

-

2/19/16 - The forms are in their final postions.

-

The bow and stern internal stems are laminated out of red oak strips.

-

2/20/16 - The Extern stems are laminated.

-

2/23/16 - The first strip is hot glued into place.

-

2/24/16 - Several strips are in place.

-

2/25/16 - More strips are added.

-

View of the bow.

-

2/26/16 - The last few inches of bow stem is covered with several detail strips.

-

2/29/16 - The port side of the hull is done.

-

3/1/16 - The overhanging strips are trimmed into a straight line.

-

The hull is fully stripped.

-

3/2/16 - The external stems are epoxied into place.

-

3/5/16 - The hull is sanded and ready for fiberglass.

-

View of the bow.

-

3/7/16 - Fiberglass cloth is laid on the hull.

-

Partially wetted out with epoxy.

-

Fiberglassing is done.

-

3/8/16 - A fill coat of epoxy is applied.

-

3/11/16 - The hull is taken off the strongback and flipped over.