-

10/5/21 - The strongback is set up.

-

10/7/21 - Jig stringers have been scarfed together and rounded off.

-

10/8/21 - Rails are epoxied to full length.

-

10/9/21 - The transom stringers are epoxied in place.

-

Scarfs are cut in the hull panels.

-

10/11/21 - The panels are glued to full length.

-

10/12/21 - The first frame is laminated from strips of sapele.

-

The jig frames are laid out on the strongback.

-

10/13/21 - The first frame is sanded.

-

Keelson support stringer is in place.

-

View down the jig frames.

-

All jig stringers are in place.

-

Keelson is test fit.

-

Second frame is laminated.

-

10/18/21 - The keelson is partially planed.

-

11/29/21 - The keelson is planed.

-

12/14/21 - #1 hull panels are epoxied in plece.

-

12/15/21 - #2 panels are epoxied in place.

-

12/16/21 - Panel #3 is epoxied in place.

-

12/17/21 - Panel #4 is epoxied in place.

-

12/20/21 - The gaps between panels are filled on the port side.

-

12/21/21 - The starboard seams are filled.

-

12/22/21 - The boat is sanded.

-

Fiberglass cloth is laid on the #1 panels.

-

The cloth is saturated with epoxy.

-

The extra glass is trimmed off.

-

12/26/21 - The boat is removed from the strongback and the frames are test fit.

-

12/27/21 - The frames are epoxied in place.

-

12/28/21 - A custom breasthook is cut and test fit.

-

The starboard rails are epoxied in place.

-

12/30/21 - The rails are sanded.

-

Forward custom bulkhead is test fit.

-

Aft custom bulkhead is test fit.

-

Bulkheads are fiberglassed.

-

A piece of fiberglass tube is embedded in the bow as an attachement point for a bow line.

-

1/1/22 - The bulkheads are epoxied in place.

-

1/9/22 - Upper edge bulkhead reinforcement is epoxied in place.

-

Deck beams are laminated.

-

1/10/22 - Inner rail for storage area is epoxied in place.

-

1/11/22 - Forward deck beams are mounted.

-

1/19/22 - Aft storage section is sealed with epoxy.

-

Forward storage section is sealed with epoxy.

-

Hatch platform supports are epoxied in place.

-

1/20/22 - The support joints are reinforced with fiberglass patches.

-

1/21/22 - Hole is cut for the hatch.

-

1/25/22 - The stainless rails for the silding seats are test fit.

-

1/26/22 - The center support for the seat rails is test fit.

-

1/31/22 - The inside of the boat is sealed with epoxy.

-

2/4/22 - Interior is partially sanded.

-

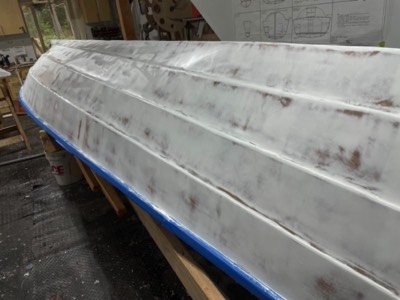

2/7/22 - The hull is sealed with epoxy.

-

2/9/22 - The hull is sanded and ready for paint.

-

2/11/22 - First coat of primer is applied.

-

2/15/22 - The primer is sanded.

-

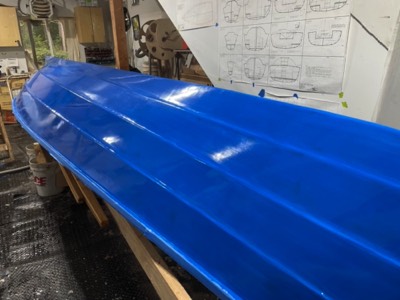

First coat of paint is applied.

-

2/17/22 - Several coats of paint have been applied.

-

2/22/22 - First coat of varnish is applied to the interior.

-

2/27/22 - Heat N Bond tape is applied around the edge of the storage area.

-

Heat shrink ceconite is used to create a watertight deck.

-

2/28/22 - Forward deck.

-

The ceconite is painted to waterproof it and protect against UV.

-

3/3/22 - The sliding seat rails are installed.

-

4/3/22 - The rest of the Poseidon sliding seat system is installed.

-

Battens to protect the edge of the fabric deck are installed.

-

3/6/22 - The forward hatch is installed and the boat is complete!