-

4/9/24 - The kit is ready to be opened.

-

4/16/24 - The #4 panels are epoxied to full length.

-

4/17/24 - Sheer clamps are epoxied on one panel.

-

4/19/24 - The rest of the hull panels are epoxied together.

-

4/22/24 - The #1 panels and two bulkheads are wired in place.

-

2/23/24 - #2 Panels and middle bulkhead are wired in place.

-

#3 Panels.

-

#4 Panels are wired in place.

-

4/24/24 - The hull is flipped and the wires are tightened.

-

4/29/24 - The aft compartment is filleted and fiberglass taped.

-

4/30/24 - The bow section is filleted and taped.

-

The cockpit section is filleted.

-

5/1/24 - Fiberglass cloth is laid in the cockpit section.

-

The cloth is saturated with epoxy.

-

The cabin section is filleted.

-

5/2/24 - Cabin area is fiberglassed.

-

5/3/24 - Carbon tube is inserted to provide a place for a carrying handle.

-

5/6/24 - The hull is sanded.

-

Fiberglass cloth is laid on the hull.

-

5/7/24 - The hull is fiberglassed.

-

5/14/24 - Patches of Dynel are applied to high wear areas.

-

5/17/24 - Cockpit seat bulkheads are tacked in place.

-

5/19/24 - Quarter knees are epoxied in place.

-

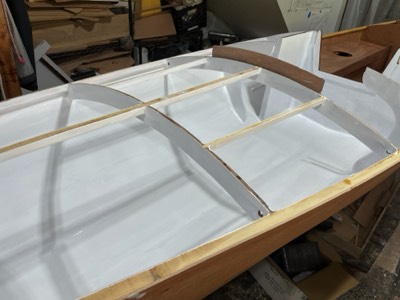

5/29/24 - Deck beams are epoxied in place.

-

6/5/24 - The daggerboard trunk is epoxied in place.

-

6/7/24 - The main mast support pieces are epoxied in place.

-

Mizzen mast support parts.

-

6/18/24 - Cockpit walls are epoxied in place.

-

6/21-24 - Inaccesible areas of the cockpit seats are filled with foam.

-

6/22/24 - The undersides of the seat tops are epoxy sealed.

-

A fill coat is applied to the cabin.

-

6/24/24 - The cockpit seat tops are epoxied in place.

-

Mast support tubes are epoxied in place.

-

6/26/24 - Seat tops are filleted and holes for hatches are cut.

-

6/27/24 - Extra face piece is added to accommodate the solar controller.

-

6/28/24 - The first part of the hatch bracket is epoxied in place.

-

Cockpit seats are sanded and the edge is reinforced.

-

Rudder trunk parts are fiberglassed.

-

7/1/24 - The main hatch is epoxied together.

-

The second companionway piece and the sliding seat support rails are epoxied in place.

-

7/2/24 - The cockpit is epoxy sealed.

-

7/3/24 - The cabin is painted.

-

7/5/24 - The companionway hatch is fiberglassed.

-

Second coat in the cabin.

-

7/6/24 - Rudder trunk is partially assembled.

-

Forward deck is partally assembled.

-

Companionway sides are temporarily fit.

-

Second stage of assembling the forward deck.

-

7/9/24 - Conpanionway board and footplace are fiberglassed.

-

7/10/24 - Hatch walls are epoxied in place.

-

7/14/24 - The underside of the aft deck is epoxy sealed.

-

7/23/24 - The electrical panel is installed.

-

Battery is installed.

-

The aft deck is epoxied in place.

-

7/24/24 - The forward deck is epoxied in place.

-

View of the deck from inside the cabin.

-

7/29/24 - Mockup of the cabin pop-top.

-

7/30/24 - The deck is ready for fiberglass.

-

The glass is saturated with epoxy.

-

8/1/24 - The inside of the cabin top is painted.

-

Navigation lights are temporarily mounted.

-

9/3/24 - Half of the hull is sanded.

-

9/4/24 - The rudder is test fit.

-

Rigger parts are cut out.

-

9/5/24 - Rudder blank and footrest mount are epoxied together.

-

Rigger edges are rounded off and holes filled with epoxy.

-

Ready for primer!

-

First coat of primer is applied.

-

9/8/24 - The rudder is shpaed and fiberglassed on one side.

-

8/9/24 - The primer is sanded.

-

The rigger is fiberglassed.

-

First coat of paint is applied.

-

9/10/24 - The rudder is fill coated on one side.

-

Second coat of paint is applied.

-

9/12/24 - Rigger mounting blocks are created.

-

Mounting blocks are epoxy sealed.

-

9/15/24 - The rigger mounting blocks are epoxied in place.

-

9/25/24 - Solar panel is test fit.

-

9/27/24 - The deck and cockpit are sanded.

-

10/1/24 - The deck is taped for paint.

-

Cockpit is primed.

-

Forward deck is primed.

-

10/2/24 - The primer is sanded.

-

First coat of paint on the cockpit.

-

Main hatch, rigger, and footbrace parts are painted.

-

10/4/24 - Several coats of paint have been applied.

-

10/5/24 - Flip side of parts are painted.

-

The cockpit is taped and nonskid is applied.

-

10/6/24 - Fist coat of varnish is applied.

-

10/8/24 - The solar panel is installed on the deck.

-

Aft hatch, all around light and steering line are installed.

-

The rudder is installed.

-

10/9/24 - The main hatch is installed.

-

Main hatch can work as a pop top or a simple prop open.

-

10/10/24 - The boat is on the trailer!

-

Bow navigation lights are installed.

-

Electrical panel with solar controller are finished.